Spray cooling

Our gentle production processes protect quality

All young animals need the best quality nutrients available in an easily digestible form to achieve optimal growth. Many nutrients are sensitive to processing and quality can be compromised by harsh treatments. Nukamel uses gentle, but effective processes to prepare its products. That starts with careful selection of the right ingredients (see dairy page) and continues with stringent testing to ensure that our products meet strict safety and quality standards. We also continually invest in developing processing innovations, so that we can provide products with the highest quality and sustainability.

Spray Cooling

Nukamel uses spray cooling technology, in which heated emulsified fat (50°C) is sprayed onto a cloud of dairy powder particles, which are cooled to -20°C.

The fat crystallises immediately due to the high temperature difference and produces a powder from which protein and fat (energy) can be utilised simultaneously by the animal.

Spray cooled dairy powders have been proven to:

- Give better digestibility and animal performance.

- Increase concentrate intake in calves.

Outstanding performance

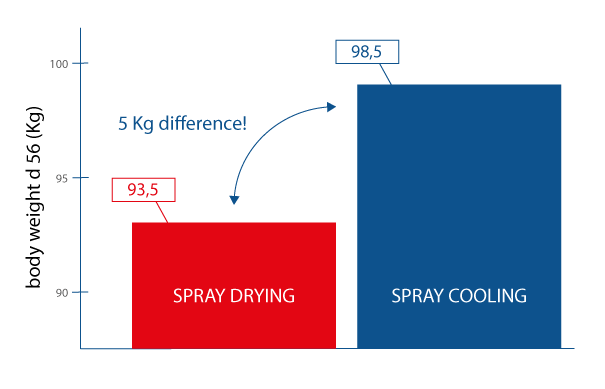

You may wonder what the significance of using this technology is. Does it lead to better performing animals? Well, yes, as a matter of fact, it does.

And we can prove it!

In our own trials, we have consistently seen the following benefits when spray cooling is compared to spray drying:

- Higher digestibility, meaning less or no nutritional diarrhoea.

- More resilient animals that require fewer antibiotics.

- Higher bodyweight at weaning.